Handheld fiber laser welding machine for aluminum stainless steel iron

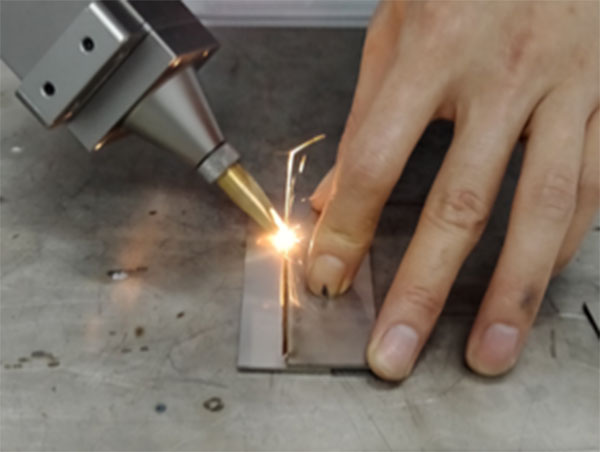

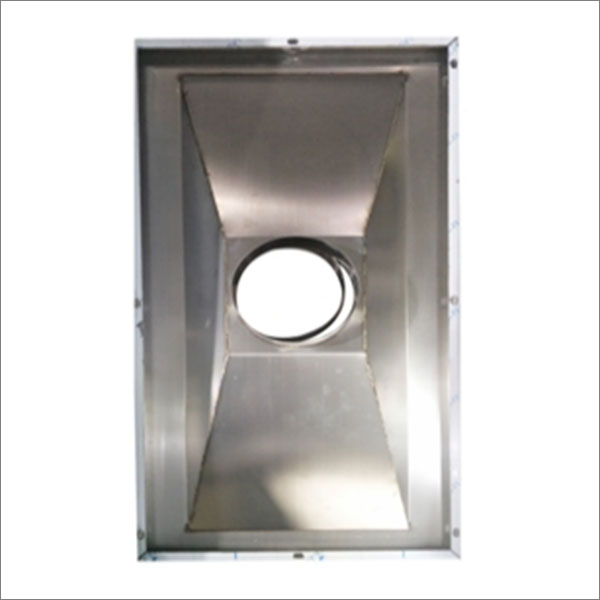

Handheld fiber laser welding machine, uses latest generation laser generator. It is equipped with wobble head and wire filler. The machines appear to laser equipment industries, fills in the blank of hand-held welding. It has the advantages of simple operation, beautiful welding beam and fast welding speed. Welding in thin aluminum, stainless-steel sheet, iron sheet, galvanized sheet and other metal materials can perfectly replace the traditional argon arc welding, electric welding and other processes. Handheld laser welding machine can be widely used in cabinets, kitchens, staircases, elevators, racks, ovens, stainless steel doors and windows guardrail, distribution boxes, stainless steel home and other industries complex and irregular welding process.

|

1 |

Machine model |

Hand-held fiber laser welding machine |

|

2 |

laser power |

1000W, 1500W, 2000W, 3000W |

|

3 |

laser wave length |

1070 NM |

|

4 |

Fiber length |

Standard10M Maximum 15M |

|

5 |

operate mode |

Continuation/ modulate |

|

6 |

Welding speed range |

0~120 mm/s |

|

7 |

Cooling chiller |

Industrial water chiller |

|

8 |

Working environment temperature range |

15~35 ℃ |

|

9 |

Humidity range of working environment |

< 70%No condensation |

|

10 |

Welding thickness recommendations |

0.5-3mm |

|

11 |

Welding gap requirements |

≤0.5mm |

|

12 |

working voltage |

220 V |

Can be widely used in cabinets, kitchen, staircase elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home and other industries complex and irregular welding procedures

The welding speed is 2-10 times faster than the traditional welding. One machine can save at least 2 welders a year.

Laser welding

Traditional welding

► The operation is simple, and it is possible to get on the job without a job certificate, and the beautiful product can be welded without the teacher.

Fillet welding, vertical welding

Stitching welding

Overlay welding

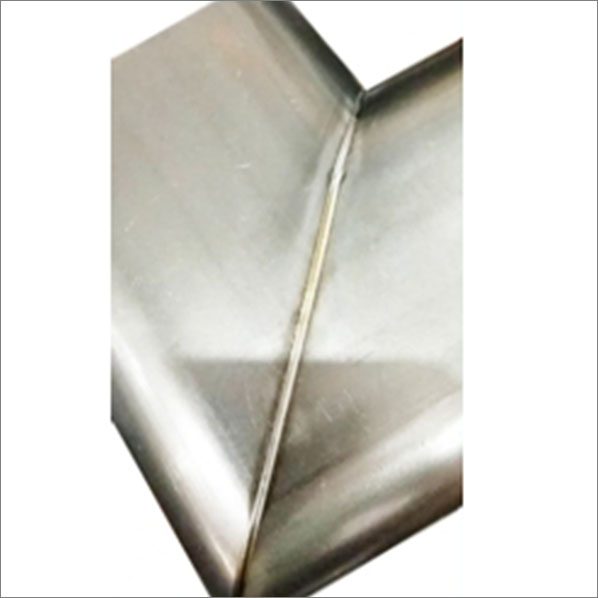

The weld seam is smooth and beautiful, reducing the subsequent grinding process, saving time and cost.

No welding scar

Beautiful weld

No deformation of the workpiece

The self-developed Wobble welding head compensates for the disadvantage of the laser welding small spot, expands the tolerance range of the machined parts and the weld width, and obtains better weld formation.

The welding workpiece has no deformation, no welding scar, and the welding is firm.

Laser welding has less consumables and long life.

Safer and more environmentally friendly.