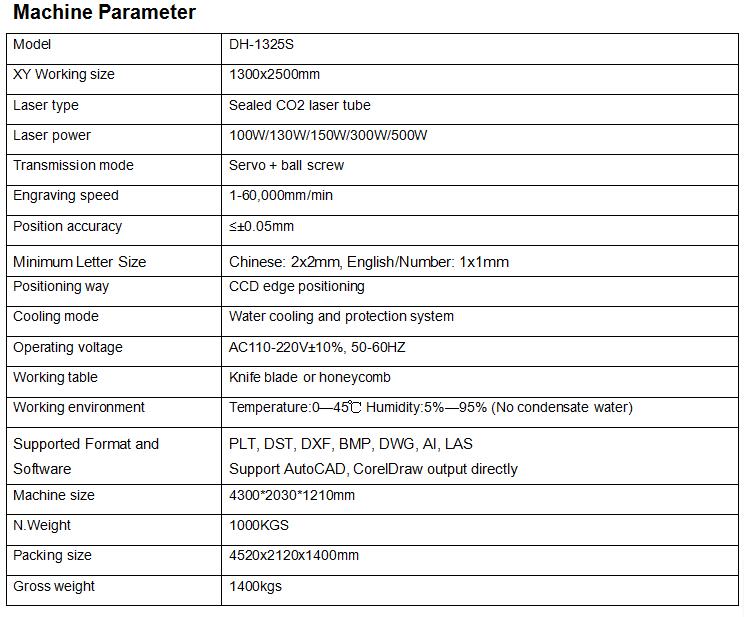

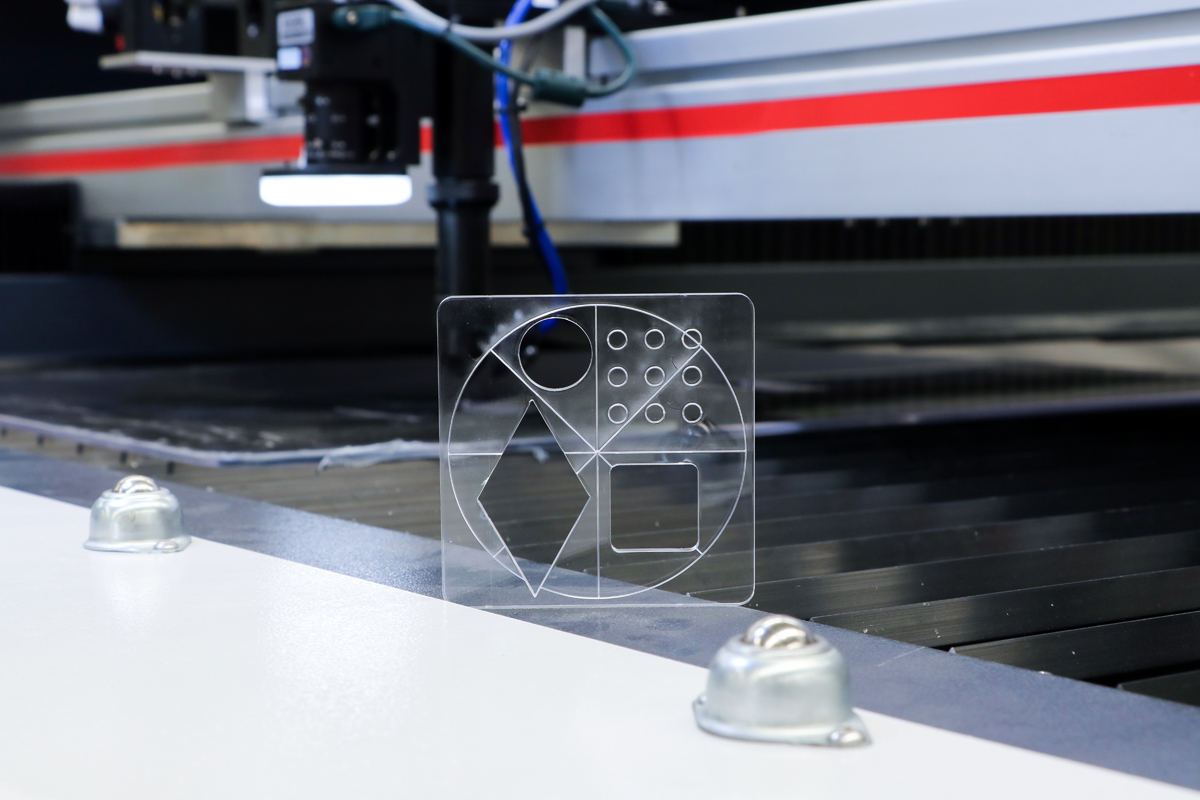

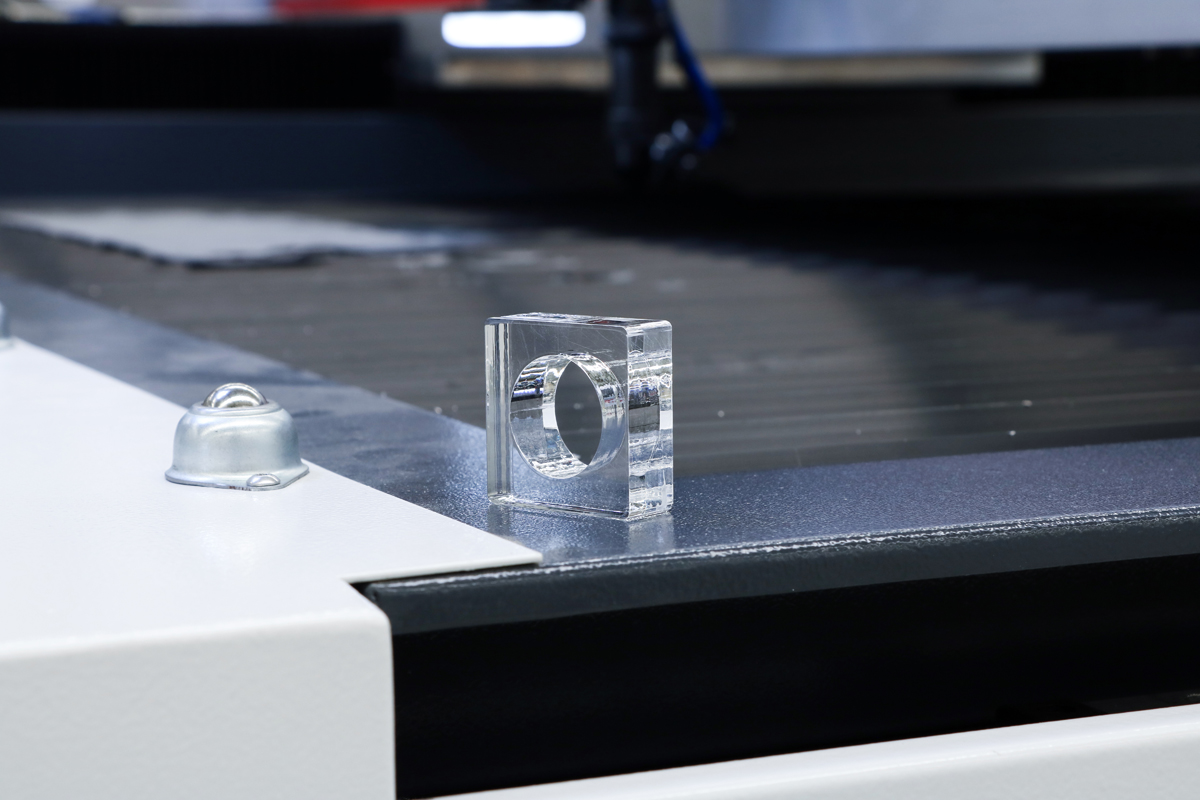

Edge finding CO2 Laser cutting and engraving machine for acrylic wood plywood mdf paper fabric with high precision

Applicable materials:

Wood, acrylic, stone, bamboo, organic glass, crystal, plastic, garments, paper, leather, rubber, ceramic, glass and other nonmetal materials.

Applicable industries:

It is suitable for cutting related industries of high-precision high-gloss organic materials/acrylic products.

Advertising industry, lighting industry, photo frame carpentry industry, architectural model industry, handicrafts, decoration industry, shoe industry, clothing proofing industry, leather industry, furniture industry, packaging and printing craft gift industry, etc.

It is developed for the convenience of customers’ high-precision cutting needs.

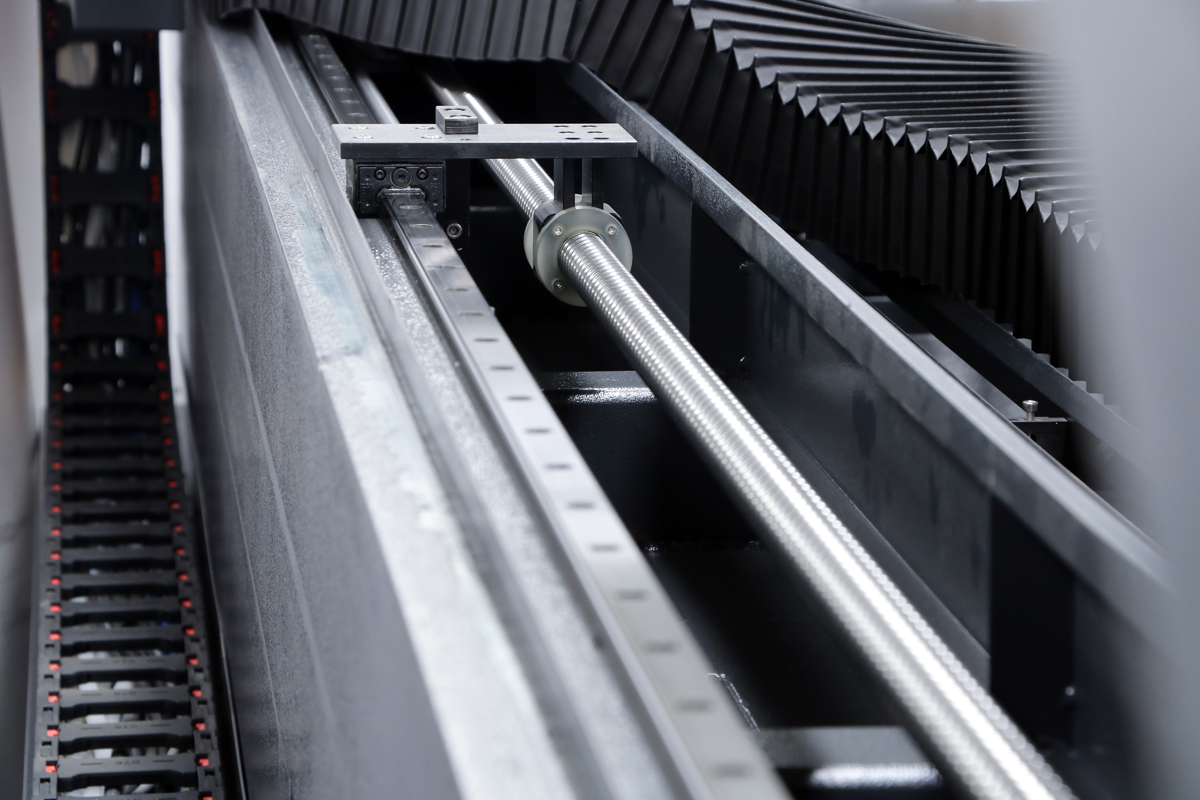

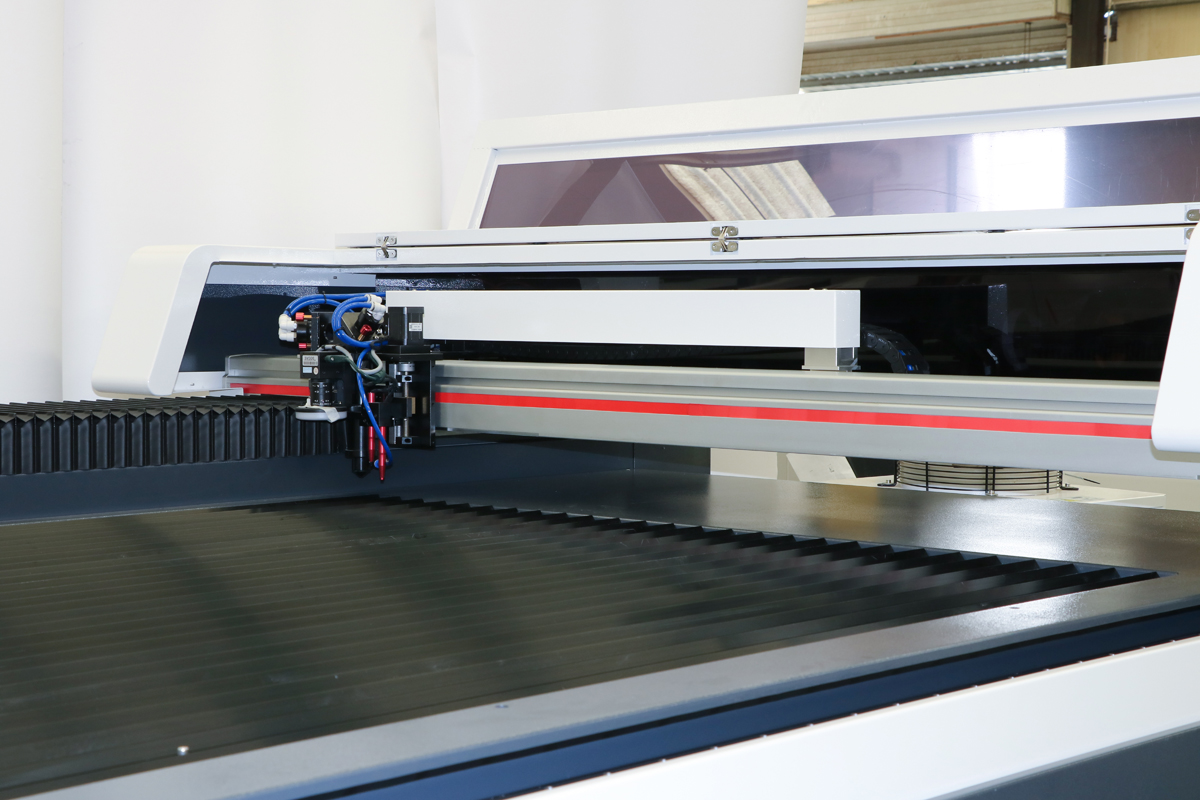

◆Professional design concept, reasonable structure, beautiful appearance, reinforced bed, the overall structure is welded with 100mm square tube, and undergoes vibration aging and natural aging treatment.

◆ The profile cast by the high-precision mold has a high strength, high stability mechanical structure, stable numerical control movement, high speed, high precision, no adjustment for long-term operation, and the cutting precision remains unchanged.

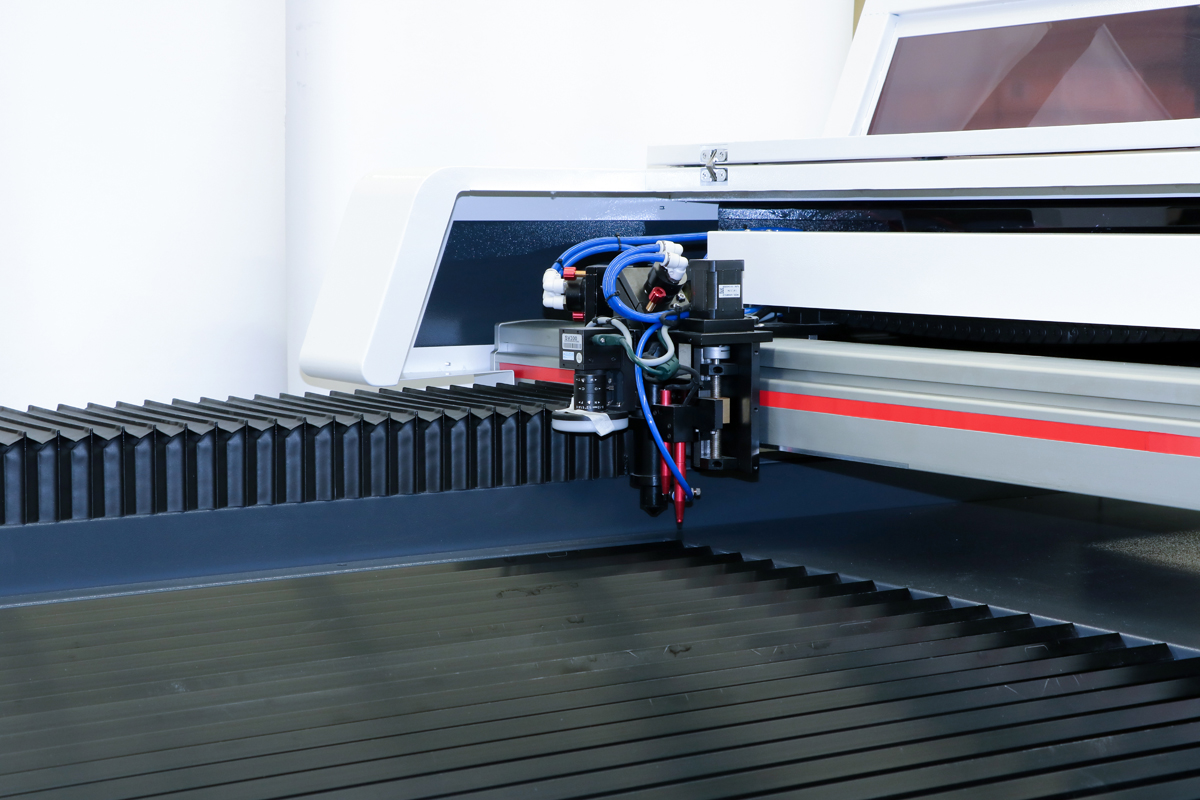

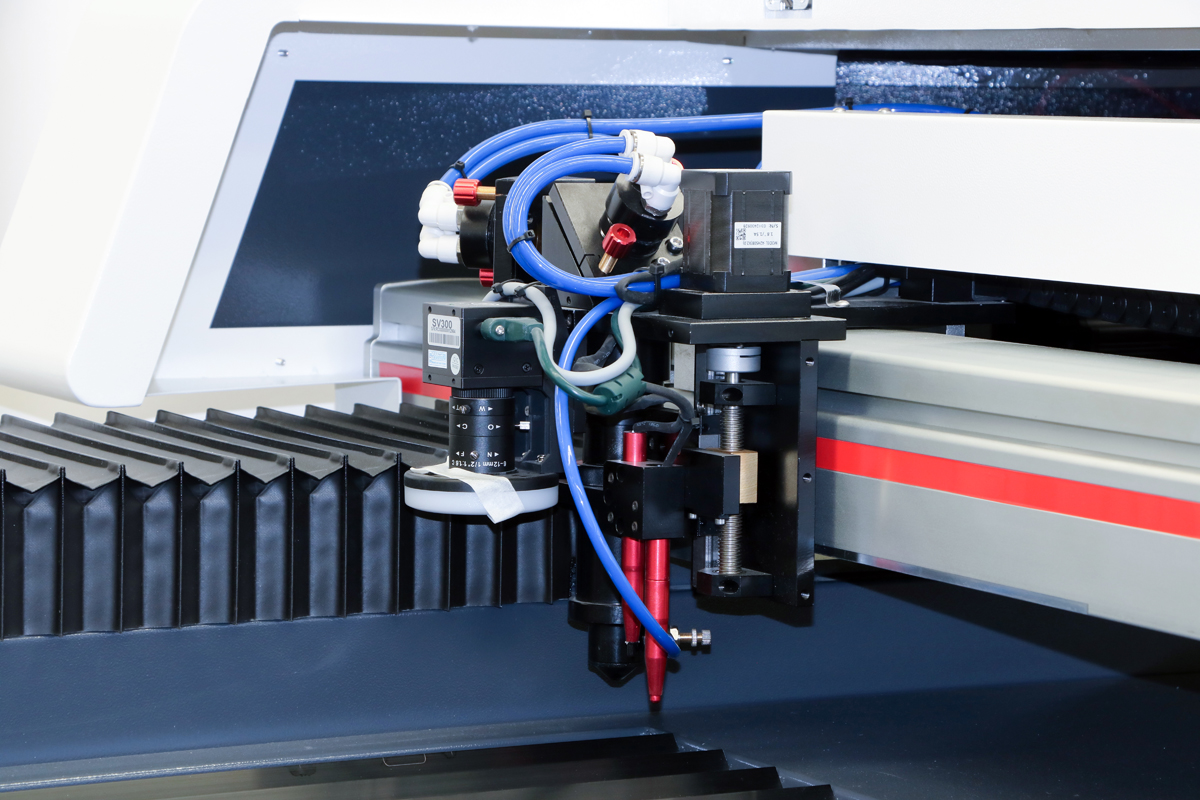

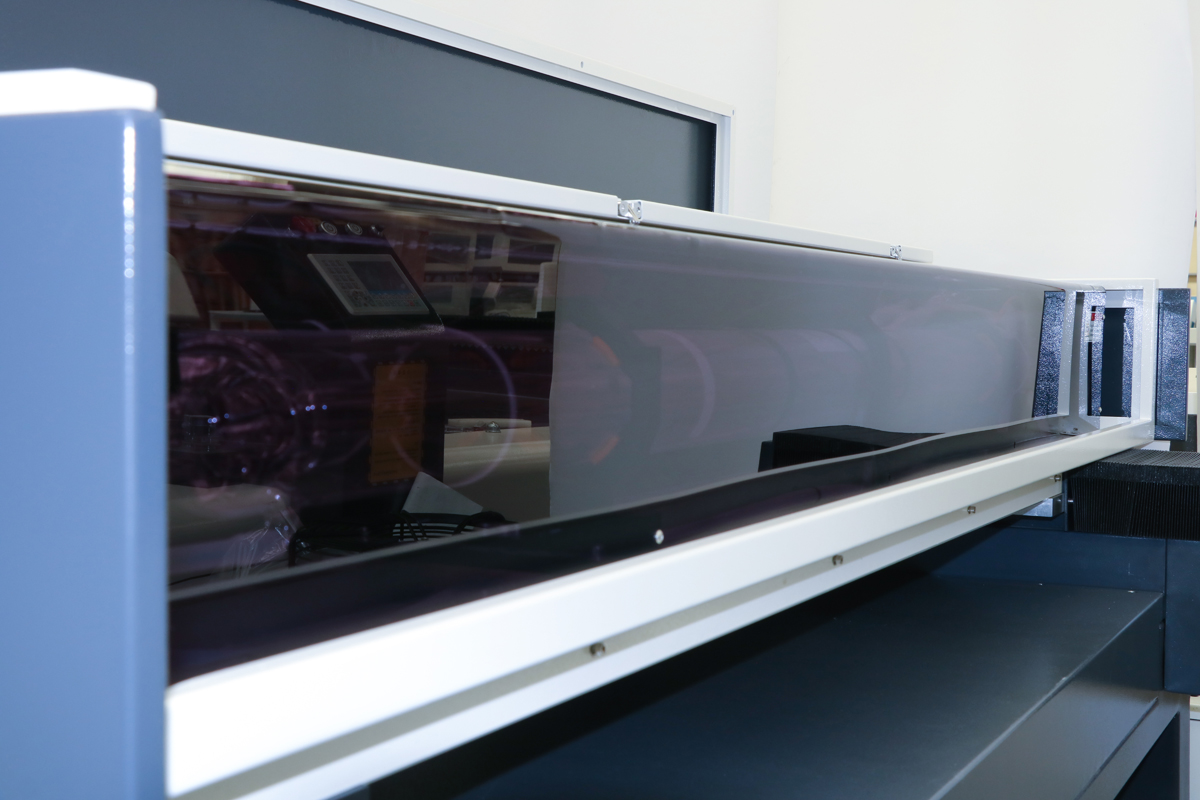

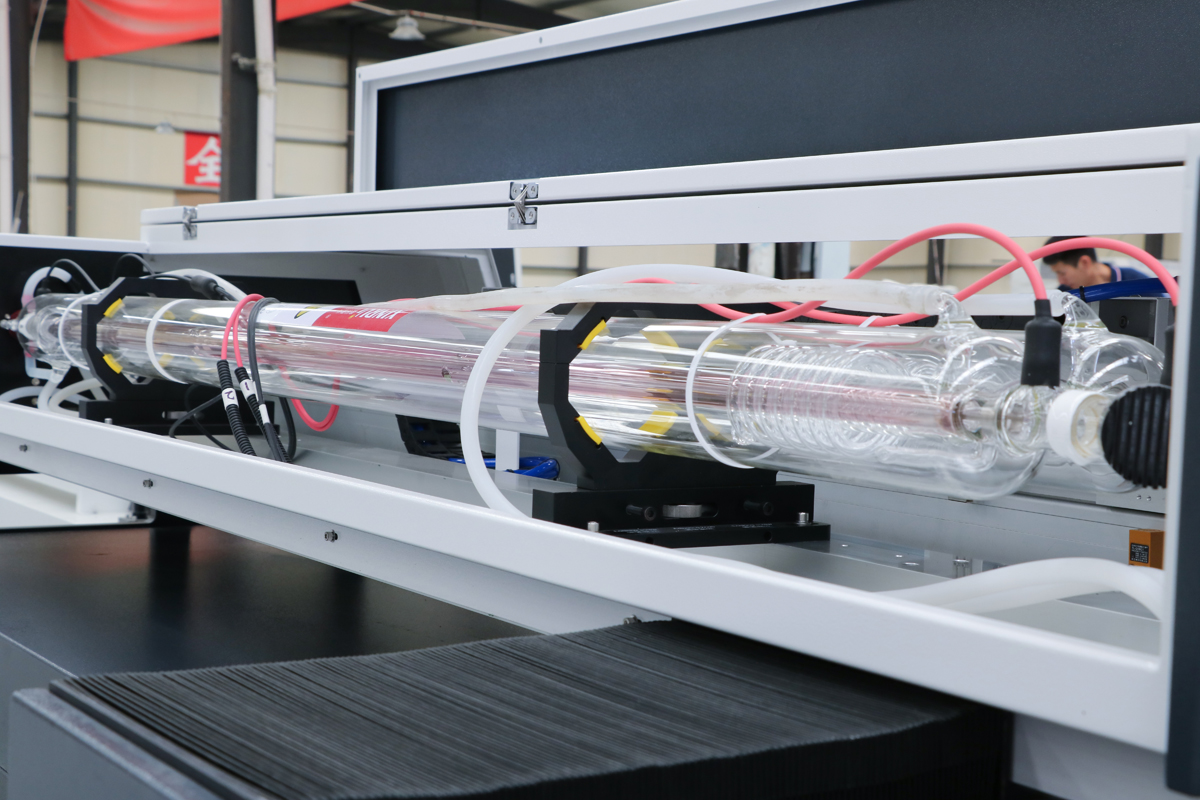

◆It adopts constant laser path design, with unique structure, small light path deviation, high stability and convenient adjustment. Optical fittings use the highest quality imported mirrors and focusing mirrors, with the highest reflectivity and transmittance among similar fittings, smaller light spot and stronger cutting force.